Ash wood furniture, its characteristics and important nuances

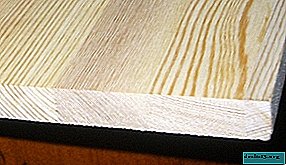

Under a furniture board is meant a material made of wood. Furniture board is characterized as an environmentally friendly basis for furniture production. The most common trees to obtain are oak, ash, beech. The wood of these trees is hard and dense. Oak is considered the first most popular. The second place belongs to ash. Namely, the furniture board ash is not inferior in quality to oak.

Distinctive features

Ash wood is characterized by a pronounced manifestation of fibrous lines, as well as the presence of a wide color gamut. Colors can be pink, yellow, red and purple. Ash board furniture has such qualities that distinguish it from many others:

- mechanical strength;

- high hardness (compared with oak, the hardness of ash is much higher);

- long service life;

- excellent elasticity;

- rare texture.

The shield of this tree is considered original due to the presence of a light core, which forms a narrow line on the lamellas.

The texture of wood is known for its attractiveness and contributes to the exclusion of colorless varnish. In the manufacture of the shield, a specific technology is used, in the process of which the resistance of the material to fire and cases of decay increases. The period of operation of the material also increases. And if the products are properly maintained, then the service life can reach a century.

Advantages and disadvantages

When using ash for furniture production, its positive properties are widely appreciated:

- representative view;

- environmental basis;

- the ability to perform many functions;

- resistance to various influencing factors;

- reliability.

The representative appearance of the furniture sheet from ash allows you to make products that look elegant and respectable in different interior solutions. The people are known for the magical properties of this tree, which speak of revival and renewal. It is believed that it maintains energy purity and prevents the penetration of negative influences into the home. Therefore, an ash board furniture is suitable for most types of furniture.

Unfortunately, its wood has some disadvantages:

- the cost of producing ash furniture has been increasing significantly in recent years;

- low resistance to moisture and putrid microorganisms.

The increase in material costs in production pays off due to high-quality and beautiful products that are valued on the market. In order to increase resistance to the influence of putrefactive bacteria in the production, various formulations are used that contribute to increased resistance. There are certain rules for the use of furniture. Operation is possible in dry, ventilated rooms without moisture. In high humidity conditions, such as in a bath or sauna, furniture can begin to be exposed to bacteria at a high speed.

Dimensions and specifications

Ash board furniture is produced by two methods of gluing and splicing finished blanks:

- whole-lamellar appearance - formed by gluing along the width;

- spliced view - glued together in width and length.

Spliced

Spliced Whole

WholeThe whole-lamella type is considered more expressive and natural. Therefore, it is used in the manufacture of outdoor furniture parts. The spliced type at a price is lower than the one-piece type. Suitable for furniture bases, countertops, staircases and window sills. Ash sheets are made in extra grade.

Humidity ranges from 6 to 8 percent. Such indicators provide constant properties of strength and reliability. The board sizes on the market vary in thickness, width and length. The spliced type assumes a single width of 0.62 m. The thickness can be 20.30.40 mm, and the length is 3 m, 1.8 m, 3 m, respectively. The whole-lamellar species is represented more with a thickness of 20 mm.

| Whole plate | Thickness mm | Width m | Length m |

| 20 | 0,62 | 0,9-2,8 | |

| 30 | 0,9 | 2,7-3,1 | |

| 30 | 0,62 | 0,9-1,1 | |

| 40 | 0,62 | 0,9-3,0 |

Ash leaf also has the following characteristics:

- hardness (according to the Brinnel table) - 4.1 kg / mm sq;

- density - 0.9 kg / m2;

- grit grinding - 80-120 units.

Use cases

In the last century, carriages and sledges were made of ash. Currently, it is used in various fields. Thanks to the unique constitution of wood, an ash board furniture is consumed in the production of various furniture details. An additional property, which is the absence of shrinkage after drying, allows you to use it to obtain frame structures for carved decorated elements. Elasticity contributes to the manufacture of spatial products of an unusual shape.

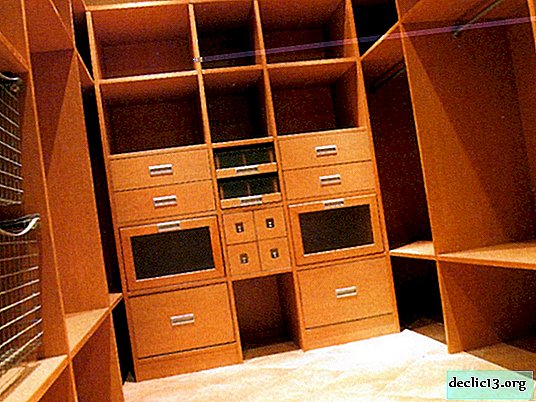

The following applications are known in the furniture sphere of wood:

- finishing the main body parts;

- processing of soft parts;

- manufacture of bases for upholstered furniture;

- manufacture of widely consumed furniture (chairs, tables, beds, chests of drawers, chairs);

- obtaining furniture elements with an aesthetic design.

Ash as a source material can be used as a solid array or in the form of veneer. Veneer is used for decoration of furniture components. Shield in the form of an array is used for the manufacture of bent forms of furniture.

Thanks to the ability to perform a variety of carvings on wood, intricate decorative elements can be obtained. And also sofas in cars, window frames, beds for looms, steps for stairs are made from ash.

Selection rules

When choosing a furniture board, the natural qualities and properties of the source material are taken into account. Due to its density and durability, the ash-tree furniture sheet belongs to those materials that are in the first positions when choosing. When you need to choose which furniture panel to purchase, certain criteria should be considered:

- resistance to load - this criterion is important depending on the purpose of the shield. The hardness of the material provides resistance to heavy loads both in furniture and other interior items. Thin sheets of the shield are suitable for furniture, and thicker ones should be chosen for the stairs;

- humidity indicator in the room - this criterion is taken into account in all situations, regardless of the processing of the material by different compositions. If the required humidity is exceeded in the room, then it is necessary to choose a moisture-resistant source material or to achieve a decrease in humidity;

- material quality - the criterion is based on production technology. Attention should be paid not only to the appearance, but also to the strength of the starting material. It is believed that shields made of radial saw lamellas are harder. But then the tangential cut is characterized by a pronounced tree structure.

When choosing a furniture board, you should focus on the purpose of using the material, because there are many options for using furniture panels.Ash furniture panel is considered a reliable and environmentally friendly material. It is in demand in many areas of furniture production. Its strength and stability are the primary features when choosing.