Kitchen from furniture panels, how to do it yourself

Everyone equips the house based on their own taste preferences and ideas about comfort. Even if you do not touch on the early stage of finishing work, and immediately proceed to the selection of furniture, many will have difficulties with its implementation. Furniture items can be purchased or made independently. The first option is faster, and the second is cheaper interesting and exciting. We offer you to learn how to create a kitchen with your own hands from furniture panels, a master class from experienced craftsmen.

Benefits of using

The created frame of kitchens from the furniture board is original in appearance, practical, highly functional and cheap decor for a city apartment or a country cottage. Such operational parameters of a furniture set are ensured by high characteristics of furniture panels. This is a very popular material today, which can be found in almost every store with building materials.

Such a wide distribution of such material can be explained by a large list of advantages that are inherent in it:

- environmental friendliness, naturalness, the absence of substances hazardous to human health, does not provoke the development of allergic reactions, has a pleasant natural smell;

- when laminating, furniture panels become resistant to moisture and deformation under mechanical stress, unlike natural wood;

- high strength, durability, practicality;

- low weight;

- hold fasteners perfectly;

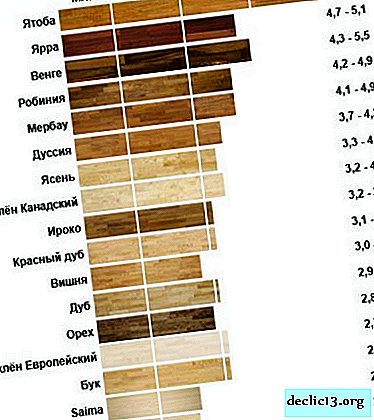

- It has a surprisingly attractive aesthetics for screws, nails and other materials. The laminated surface of the material is made in a variety of color shades of tree species, so you can make a furniture set that matches the color of the room decoration;

- affordable cost. Furniture is conveniently made from such materials afterwards, so that its cost ultimately comes out very budget. In addition, doors for the kitchen are also made from furniture type shields.

Furniture panels, from which it is worth making a kitchen, are practically devoid of flaws. Therefore, experienced craftsmen recommend that consumers focus on this material. And how to make a kitchen on your own with their furniture panels, we will describe further.

Design

Before starting work on the manufacture of kitchen furniture from furniture panels, it is important to prepare a plan for the phased implementation of the work. It should contain information regarding:

- the type and composition of future furniture;

- relevant in the process of work materials, accessories;

- necessary tools;

Some little things in practice can be very important. If you leave them unattended, some difficulties may arise in the future.

Next, you can proceed to the creation of the project. It is necessary to determine exactly how many cabinets, cabinets, wall corners, shelves. All elements of the kitchen should be detailed: it is necessary to carefully describe all the geometric dimensions of each piece of furniture. Calculate the actual number of shelves, all types of hardware (handles, hinges, fasteners, fasteners on magnets). Consider the presence of a built-in sink, stove, hob, oven, gas water heater, washing machine. Make a decision about the shape and shape of the facades, remembering that it may not be possible to make structures that are too complex. Experienced craftsmen advise you to evaluate your strength, it may be easier and faster to order facades in the store. Also think about whether you want to equip the kitchen with glass doors, shelves. Such elements of a kitchen set will need to be selected in advance.

After the project is created, it will be necessary to purchase all the necessary materials, to make cutting of furniture panels. If this stage of the work was carried out without errors, it will only be necessary to assemble the individual parts into a complete structure.

Materials and Tools

Making a kitchen frame with your own is a great way to show your own skills, talent, individual taste. In addition, this is a great way to decorate your home without huge material costs. High-quality exclusive furniture design, created by yourself, will be the real pride of the owner of the house.

To make a kitchen from furniture panels, you need to acquire such materials and devices:

- furniture panels in the right amount. Material parameters can be different: width within 200-600 mm, length - 600-2700 mm;

- screwdriver;

- Sander. If it is missing, you can limit yourself to fine sandpaper. However, working with it may take some time;

- self-tapping screws;

- electric drill;

- wood hacksaw or power saw;

- centimeter, long ruler;

- a simple pencil;

- varnish coating;

- Screwdriver Set;

- all kinds of fittings.

This is the simplest and most affordable list, but you can expand it if you wish. Much in this case depends on the complexity of the design and design of future furniture. The main thing is to work, adhering to all safety standards, then the work will be quick, interesting.

Furniture panels

Furniture panels Tools for assembling a kitchen headset

Tools for assembling a kitchen headset

Production of furniture board

Before we talk about the features of its manufacture, we explain what a furniture board is. In practice, this is a natural material in the form of wood sheets. They can have various shapes and are intended for the production of furniture and stairs. The most common furniture panels are made of coniferous wood; a little less often can be found on the domestic market birch or oak.

To create a furniture board, manufacturers use rather small elements, so the material is quite low in cost. Prices for solid boards are indeed much higher, and operational parameters are almost at the same level.

If high-quality, well-dried wood was used in the manufacturing of the furniture board, then it will have high operational parameters. Therefore, when buying material in a store, it is important to be vigilant, to prefer a better option.

Assembly steps

To assemble furniture from furniture panels into the kitchen, as in the photo, you will need to perform a series of actions in a certain sequence and prepare drawings. It all depends on which piece of furniture is specifically manufactured. We describe the most relevant options for the kitchen below.

Table

The process of making a kitchen from a furniture board can begin with the creation of a dining table with your own hands. A table made of such materials is practical, durable, and durable. Possible table shapes from furniture panels and methods for their manufacture are described in the table

| Countertop shape | Manufacturing technology |

| Rectangular | Experienced craftsmen are advised to limit themselves to a simple rectangular shape, if there is little experience in such matters. This design is created from a solid shield measuring 2700x600 mm. |

| Rectangular with smooth corners | A rectangular countertop can be made more interesting in design, you can smooth its corners. |

| Square | If you want to make the countertop square, you should use an electric saw and saw off the extra centimeters. |

| Round | If you want to make a table with a round tabletop, you need to cut out two semicircles of two shields of the same radius. Further, such halves are connected to the countertop using transverse bars. And so that the joint is not too conspicuous, they coat it with PVA glue, dry it, and then polish the front side. |

| Oval | If you plan to make the table oval, then between two halves of the circle you will need to insert a rectangular insert. |

When the countertop is made, it is reinforced with stiffeners on the underside with the help of bars. Further, to this element of the future table from the shield, it will be necessary to fasten the elements for fixing the supports. Drill holes for them in advance. Finishing the table involves the final grinding of surfaces and painting with varnish.

Preparation of furniture board

Preparation of furniture board Cut the oval part of the countertop

Cut the oval part of the countertop The process of multi-layer varnishing

The process of multi-layer varnishing Preparation of table legs

Preparation of table legs Veneer countertops

Veneer countertops Underframe layout

Underframe layout Foot fixing

Foot fixingCupboard

A kitchen cabinet can also be made with your own hands from a furniture board. At the initial stage, it may seem that the task is overly complicated, but this is not entirely true. All work is conditionally divided into three stages:

- preparatory work involves the procurement of relevant tools, materials, creating a product design;

- assembly - since the cutting of the parts of the product is done in advance, you will need to assemble them into a single design. To do this, take a screwdriver and screws. Alternately attach the sidewalls to the rear wall of the structure, then the cover and the bottom. In the end, you only need to attach the facade and supporting legs so that the kitchen cabinet is ready. If you plan to move the structure during operation, it is better to prefer the wheel support. If the cabinet at the end of the work seemed too low, select supports for it with the function of changing the height;

- finishing work involves grinding, varnishing or painting the surfaces of the furniture board, decorating the cabinet with a handle.

Collection of cabinet walls

Collection of cabinet walls We design the bottom of the cabinet

We design the bottom of the cabinet Mounts

Mounts Door manufacturing

Door manufacturing Ready-made kitchen cabinet

Ready-made kitchen cabinetMounted elements

Kitchens made of furniture panels often include hinged elements. These are convenient regiments, lockers in operation which differ in high capacity, practicality. The schemes for their creation are quite simple, and the work on their production will take a few minutes. But in the manufacture of such furniture it is important to consider their features. And they consist in the method of their installation on a wall surface. Installation is carried out using special loops that are fixed in the upper corners of the rear wall of the cabinet.

Properly calculating the weight of the cabinet along with the contents, you can create a convenient kitchen. To do this, determine how many kitchen utensils you plan to store in a particular hanging cabinet, because excessive loads for hanging structures without reinforced fasteners are not permissible. For a beautiful service, you can prepare an open shelf, for bulky pans - a spacious corner cabinet with reinforced fastening.

Finishing process

Designs made of a furniture board for a kitchen can be opened after assembly with varnish, which will significantly increase the wear resistance of surfaces and give them an attractive look. To do this, the furniture is polished, varnished, dried indoors. Do not forget that drafts will only spoil the process. Lacquered cabinets and cabinets look classic, concise, stylish.

Almost the same technology is used when painting furniture from panels. Only after grinding, the surface should be smeared with soil, and only then painted. Then the paint will hold on better. If you want to apply some original idea, then it is better to refuse varnish and paint.

We will describe the simplest, but at the same time very interesting ways of decorating kitchen furniture, which was made independently, without the help of professional furniture makers and expensive equipment, namely:

- use of photo wallpaper - cover parts of the cabinet with newspaper and fix it with tape. In these areas, wall murals will subsequently be glued, and the remaining parts can be painted;

- create the effect of antiquity - for this decor technique you will need to use foam baguettes with curls. They are cut and fixed with liquid nails on the cabinet doors. Next, the entire structure is painted, and after drying the paint using some corners and curls with sandpaper, some scuffs are left. If you want a gloss, then you can use a sponge on the curls of a baguette to apply gold strokes.

The next video details the design options for hand-made kitchen furniture from panels.